Adhesive handle application on the side of the product

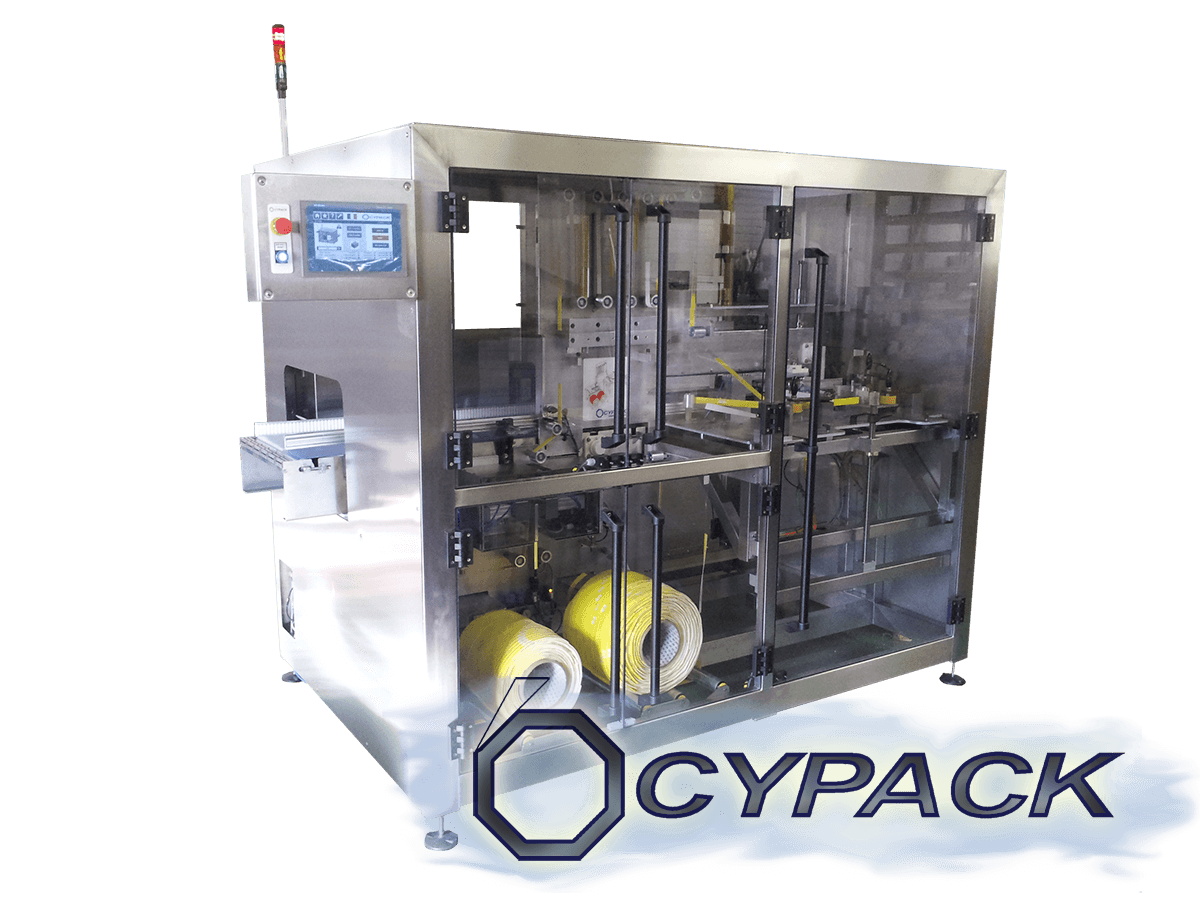

Our machines are available in single, double and triple lane to meet your needs.

Our patented systems allows the use of prelaminated adhesive tape (label already present on the roll) as well as neutral adhesive band (label dispensed by the machine throughout the roll unwinding).

HANDLEPACK - S SIDE

- High speed adhesive handle application on the side.

- Cadence: up to 80 cycles/min/lane.

HANDLEPACK - L SIDE

- Very high speed adhesive handle application on the side.

- Cadence: up to 150 cycles/min/lane.

Options & Technologies

Control Panel

HMI allows to set up the machine, to adjust the differents settings, to change formats or access admin’s parameters in the user’s language.

Emergency stop is available next to the touchscreen. The control panel keeps the operator informed of all relevant operating states.

![]()

Automatic Splicing

The unwinder ensure an homogeneous adhesive distribution in the machine circuit, it is securised with an electromagnetic brake for consumable replacements. Easy access for maintenance operations.

The double unwinder allows quick changeover of adhesive reels, and can also be fitted with an automatic splicing system for uninterrupted production while consumables are being refilled.

Labels Box

The labels box supply the machine with variable sized labels depending of the chosen format. The gluing on the adhesive tape is done with and electromagnetic cylinder.

The labels reloading can be easily done during the course of the machine, the format change is fast and easy to set up.

Stainless Steel

Protected from limited dust ingress. Protected from water spray from any direction.

The materials used to construct the machinery make it a strong and effective tool for heavy use.